Vol. 39 (Number 48) Year 2018. Page 1

MELENDEZ, Jesus R. 1; ZOGHBE Nuñez, Yamil Abdallah 2; MALVACIAS Escalona, Anny Macarena 3; ALMEIDA, Grace Annabelle 4; LAYANA Ruiz, Javier 5

Recibido: 29/06/2018 • Aprobado: 01/08/2018 • Publicado 29/11/2018

ABSTRACT: The investigations began with the drum-buffer-rope architecture, as the basis of the Theory of Constraints (TOC). Currently, TOC has been applied in various business sectors. With the support of mathematical models and simulation, it has been possible to optimize the productive processes. The objective of this study was to determine the investigative tendencies of the TOC in the different productive sectors and its application in business management environments. The results establish that its application increases the efficiency of the process. |

RESUMEN: Las investigaciones comenzaron con la arquitectura drum-buffer-rope, como base de la Theory of Constraints (TOC). Actualmente la TOC ha sido aplicada en diversos sectores empresariales. Con el apoyo de modelos matemáticos y de simulación, se ha logrado optimizar los procesos productivos. El objetivo de este estudio fue determinar las tendencias investigativas de la TOC en los distintos sectores productivos y su aplicación en entornos de la gerencia empresarial. Los resultados establecen que su aplicación eleva la eficiencia del proceso intervenido. |

In the decade of the 80s, studies were developed towards optimized production technology, and in 1984 "The Goal" was published, first described by Eliyahu Goldratt which produces a cut in the evolution of optimization models (Goldratt, 1996). In this period, different management philosophies were implemented; one of them was the Theory of Constraints (TOC), which represents a global management philosophy that considers that the organization works to make profit. Therefore, it is applicable in processes that interfere and prevent companies from reaching their goals and net profit (Goldratt, 2008).

Originally TOC was used to plan the production process and allocate resources (Verma, 1997), but the scope of its content has evolved in new globalized scenarios, loaded with advances in technology (Watson, Blackstone, & Gardiner, 2007), the demands of consumers and the competition between rival companies. In this sense, TOC perspectives are broad and can be integrated as a management philosophy to the different management processes (Izmailov, 2014). TOC evaluates the processes as links of the same chain and considers them dependent on each other (Şimşit, Günay, & Vayvay, 2014) and, studies the relationship of these bottlenecks, which describes it as an important tool to eliminate problems at the base in the use of the drum-buffer-rope architecture. In short, the principle of the Theory of Constraints (TOC), establishes its application in the weakest links of the chain, considering them equally strong (Avraham & Goldratt Institute, 2009).

Currently, companies within the global scenario must use their resources efficiently in each of their production processes, becoming more competitive in the markets related to their action as a company, this way of acting guarantees sustainable permanence and financial growth. In this sense, the perspective of the Business Management is focused on implementing a process of continuous improvement that allows the fulfillment of its goals. These reasons lead to a managerial vision focused and directed to the understanding of its strategic structure under the processes approach, broadly considering the production and service sectors (Okutmuş, Kahveci, & Kartašova, 2015).

In these business scenarios, global management visualizes the need to increase efficiency in the production and good services, and this includes the different business sectors, including complex industrial projects, educational sectors (Fekri, Shafiabady, Nooranipour, & Ahghar, 2012 ), hospital sectors (Aguilar-Escobar, Garrido-Vega, & González-Zamora, 2016), and cost accounting systems (Avraham & Goldratt Institute, 2009). From these different organizational sectors the TOC participates along with other management tools simultaneously (Izmailov, Korneva, & Kozhemiakin, 2016a) to obtain a solution to the problems that arise in the process lines. Therefore, modern management and its administration are aware of the importance of the company's performance and therefore avoid running the risk of canceling its operations (Izmailov, 2014). This means that we are in the presence of management techniques and methodologies that are currently combined to increase organizational productivity. These techniques include all processes, like it costs (Salazar, Villavicencio, Corral, & Melendez, 2017), manufacturing, human resources and other. In this direction, we can relate the evaluation and risk management (Rangel, Salazar, Salazar, Malvacias., & Vacacela, 2017) and aspect corresponds to the participation of employees in decision making, based on the results obtained (Melendez, Malvacias, & Almeida, 2018). Thus the TOC established an innovative approach for management sciences and general administration, with an easy application in the international business context. In short, its scope of action covers all strategic, functional and operational levels of organizations.

The objective of this study was to determine the investigative tendencies of the Theory of constraints (TOC) and their application in the different business and academic productive sectors from the conception of business management. The methodology of this paper focused on a systematic review of scientific production, related to the Theory of Constraints. The search was carried out in Elsevier’s publishers through the search engine ScienceDirect, Esmerald publishing, Taylor & Francis on line; in the Scientific electronic library on line (Scielo) and with indexation in Scopus and others. A bibliometric (Spinak, 1996) and content analysis was applied (Bardin, 2002). Some indicators of scientific importance are considered as number and distribution of publications, by countries and journals (González de Dios, Moya, & Mateos Hernández, 1997). The results obtained are shown in summarized tables. The findings show how TOC has increased its participation in academic publications indexed in recent years, and has been considered by management in diverse areas, as an important alternative for the optimization of production processes.

The research is classified as a systematic literature review of the Theory of Constraints, exploratory and descriptive. It is based on a bibliometric (Spinak, 1996, López, 1996, Ferreiro, 1995) and content (Bardin, 2002) analysis. Some indicators of scientific importance as number and distribution of publications by countries and journals (González de Dios et al., 1997; López Piñero, & Terrada Ferrandis, 1992) will be considered. The findings will be presented in tables of contents designed for the transcription of the material compiled from selected documentary sources. Three phases in the investigation are considered:

Phase 1, published articles related to the TOC theme were globally reviewed. The search was carried out in Elsevier’s publishers through the search engine ScienceDirect, Esmerald publishing, Taylor & Francis on line; in the Scientific electronic library on line (Scielo) and with indexation in Scopus and others. Criteria to locate the articles were discriminated in: Refine by year: 1997- 2018; Article type: research articles & review of articles; the key words or acronyms: "Theory of Constraints; TOC; Theory of Restrictions and management * ". Published articles of the Scopus and Scielo indexed bases are considered as the main ones without excluding other bases.

Phase 2, was based on the selection and definite classification of articles, without restriction of the language and that its theme is within the context and managerial approach. The information of the selected articles was transcribed into an Excel file, cataloging the variables of each publication with the author's name, title, unit of analysis, found findings, location of the country where the data was taken and date of publication. Methodology models of the publications of other authors are highlighted (Şimşit et al., 2014; Ruiz-Torres, Ayala-Cruz, Alomoto, & Acero-Chavez, 2015).

Phase 2 is divided into two sub-levels:

The initial process concluded with the selection of 41 articles published in 24 academic journals. Each of the articles was examined by the research team. In this process, articles were eliminated because they did not meet the selection criteria, basically due to inconsistencies of the topics.

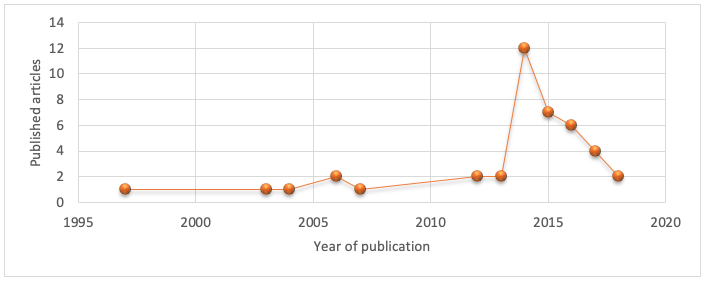

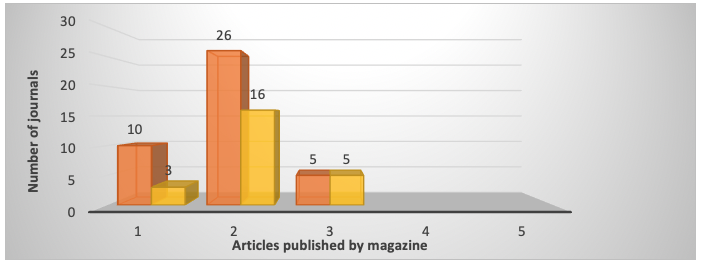

A classification of the indexed journals is carried out, the name of the journal, number of published articles, country of edition of the journal and the affiliation center is considered, see table 1. In this sense, the distribution of published articles by year and, the number of articles published for each selected journal are discriminated, see figure 1-3

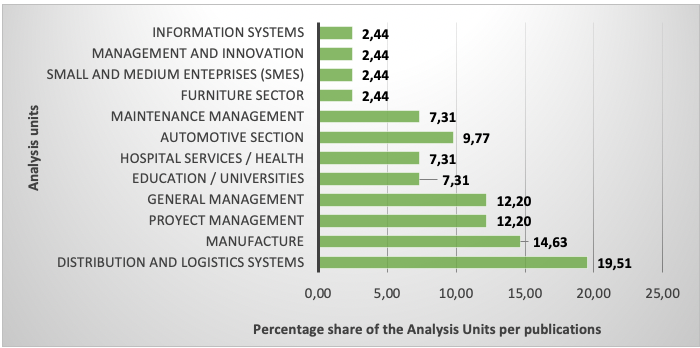

Phase 3, in this phase the articles were grouped into axial categories. The first one, according to their unit of analysis, which considers the sector or topic of application of the TOC in the management area where the research was carried out, see figure 4, and, the second, based on the methodology of data collection in each investigation: case studies, literature review, multicentric research, see figure 5. The third category considers the topics addressed consistent with the use of TOC in the framework of managerial reference, according to the units of analysis and objectives, table 2. The findings of phases 2 and 3 are structured in tables of contents and figures in order to perform the analysis of the results.

We proceeded according to the analysis of the categories studied, described in the research phases. The results are described according to the data shown in the tables and figures.

41 documents were selected according to the criteria defined by the researchers, and the results show that in the period between 1997-2013, the production of articles remained constant, accumulating 10 publications, representing 24.39% of the total amount considered in this investigation. In 2014 there was a peak and the figure of 12 publications was achieved, representing in just one year 29.27% of the total published in the revised period. If the whole set is considered from 2014 to 2018, the figure reaches 31 publications, for 75.61% of the total sample in the entire time base which was considered.

In this sense it is shown that the period between 1997 to 2013, maintained a low average production, with 1 article per year and, a break point in 2014, with an increase in production to 12 items and a later stage that begins to decrease, although it still represents the largest amount recorded and accumulated. Although these two periods show a low level of publication, which indicates that it is not a frequently developed topic, however, there is a tendency to grow with exponential characteristics (Price, 1963), which are evident since 2014. In this context, results suggest a tendency to the growth of more investigations related to the theme of the Theory of Constraints (TOC), see figure 1.

Figure 1

Number of articles published per year

A bibliometric indicator (López Piñero, & Terrada Ferrandis, 1992), which highlights the place or country where the journal is published is considered. In this case, the amount of articles published and grouped according to the country where the journal is published are shown. The distribution is among 11 countries where the production of 41 scientific articles is concentrated. The participating countries and the number of articles published, include: The Netherlands 10; Colombia 8; United Kingdom 7; Venezuela 6; Germany 3; The United States 2; Italy 1; Spain 1; Lithuanian 1; Brazil 1; Denmark 1, see table 1.

In this sense, we are in the presence of three geographical areas that carry out publications on the subject studied. European bases generally concentrate a total of 7 countries for 63.64% of the total participating countries in this period, followed by the Latin America region with 3 countries and 27.27% and North America with 9.09%.

Three countries are presented, in descending order, which have a large production activity on this issue, they have published 25 articles in the evaluated period. These countries are: The Netherlands, Colombia and, The United Kingdom, which concentrate 60.98% of the total publications in the evaluated period. Grouping only some Latin American countries, such as Colombia, Brazil and Venezuela, they have accumulated 15 articles for a participation of 36.59%. This difference allows us to identify a positive trend in considering this issue as important in the Latin American region, in journals that have a publication profile in the areas of management, administration and accounting. Another result according to the place of publication of the magazine and, which concentrates five published articles, are Germany, and the United States, with 12.20% of the total amount published and, the rest of the publications are grouped in five countries, which have presented a single article each one, for a total of five publications under this theme from a managerial approach, which represent 12.20%, see table 1.

Table 1

List of Journals and number of articles published by countries

Journal |

Number of publications |

Place of edition / Country |

Affiliation by Research Center / country |

Applied Mathematical Modeling. |

1 |

Netherlands |

Taiwan |

Business Process Management Journal |

1 |

United Kingdom

|

Brasil |

Central Bank review. |

1 |

United Kingdom

|

Turkey, London & United States |

Chaos, Solitons and Fractals |

1 |

Italy |

China |

Computers and Industrial Engineering |

1 |

United Kingdom

|

Taiwán |

Cuadernos de contabilidad. |

1 |

Colombia

|

Colombia |

Dimensión Empresarial. |

1 |

Colombia

|

Colombia |

DYNA. |

1 |

Colombia

|

Colombia |

Estudios Gerenciales. |

3 |

Colombia

|

Colombia, Cuba, Colombia |

European research on management and Business economic. |

1 |

España |

España |

Expert Systems with applications. |

1 |

United States

|

España, Portugal |

Intellectual economics |

1 |

Lithuanian

|

Lithuanian

|

International Journal of Production Economics |

3 |

Germany

|

China, London, Portugal, United States, United Kingdom |

International Journal of Quality & Reliability Management |

1 |

United Kingdom

|

United Kingdom, Jordan

|

Journal of applied logic.

|

1 |

Netherlands

|

Serbia |

Journal of Enterprise Information Management. |

1

|

United Kingdom

|

India |

Journal of Strategic Marketing |

1 |

United Kingdom

|

India, United States |

Journal of Operations Management |

1 |

United Kingdom |

United States |

Espacios. |

6 |

Venezuela |

Colombia (1), (5)Brasil |

Revista INNOVAR. |

2 |

Colombia |

Colombia, México |

Omega (International journal of management science). |

1 |

United States |

United States |

Production. |

1 |

Brasil |

Brasil

|

Procedia Social and Behavioral Science.

|

8

|

Netherlands

|

Turkey(2), Russia(3), Lithuania (1), Iran(1), Slovakia (1), Italy (1) |

Total Quality Management and Business. |

1 |

Denmark |

China |

The production of research related to TOC is divided into 24 journals, which store the selected sample of 41 articles. In relation to the number of articles published for each journal, it is evidenced that the three journals published in Netherlands concentrate 10 publications; Venezuela with one magazine has published 6 articles; five Colombian magazines have 8 articles; three magazines between Germany and the United States have 5; The United Kingdom has seven journals with 7 publications; and five remaining magazines contain 5 articles.

Configuration shows that only three journals accumulate 10 articles of the total production of 41 articles. This means that 12.5% of the total number of journals publish 24.39%. If we group the number of journals of the countries of Venezuela, Colombia, the United Kingdom, Germany and the United States, a total of 16 Journals and 26 published articles would be reached, this represents 66.67% of the total journals reviewed, which group 63.41% of the published articles. The difference would be represented by five Journals that have published at least 1 article each, 20.8% of the journals and 12.20% of the publications. In general terms, we are in the presence of a low scientific production defined by the level of dispersion in the period and number of publications, see figure 2.

Figure 2

Number of articles published by journal

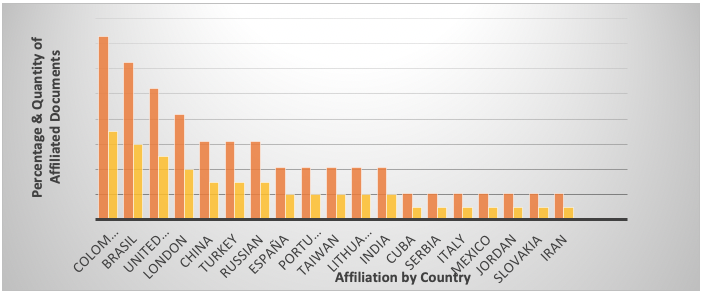

The results show the tendency of affiliation by country of production of articles, 48 different affiliations have been obtained. Four groups are shown according to participation percentage, where group one, concentrates 18 affiliations for 37.50% of the total sample, and is made up of Colombia, Brazil, and the United States; followed by London, China, Turkey and Russia with 13 affiliations and 27.08%; the third group includes: Spain, Portugal, Taiwan, Lithuanian and India, with 10 affiliations and 20.83%; the fourth group includes Cuba, Serbia, Italy, Mexico, Jordan, Slovakia, and Iran, accumulating a total of 7 affiliations and 14.59%. These results allow us to realize that the TOC is being considered in exercises that involve the optimization of productive processes in certain countries with greater speed and quantity than in others, see figure 3.

Figure 3

Affiliation of scientific production by countries

According to the type of research application by business sector, the results show the units of analysis according to the business areas, classified as, the Distribution & Logistics Systems, Project Management, Manufacturing and General Management, are units of analysis that group and dominate, accounting 58.54% of the total published. A second group of publications based its units of analysis in: Education / Universities, Hospital Services / Health, which represent 14.62%. A third group of units of analysis by sector is formed by the automotive, maintenance management, furniture, small and medium enterprises (SME), Management and Innovation and computer systems, which account to a 26.84% incidence. If specific figures are considered, it is noted that the leadership of publication in the business areas is distributed in the Distribution and Logistics Systems, with 19.51%, Project Management and general management, both with 12.20% and Manufacturing with 14,63%. These sectors are formed by complex administrative processes, and this is where more research has been carried out with implications for the application of TOC. It also shows two interesting sectors with an incidence on the study of their processes, these are the automotive sector with 9.77% and the maintenance sector with 7.31%, although with a lower participation, there is a good background for future research.

These data show a general trend in the use of TOC in business areas composed by processes that require continuous operation to respond to direct clients and a low incidence of research in areas classified as general services, see Figure 4.

Figure 4

Distribution of publications according to the Units of analysis

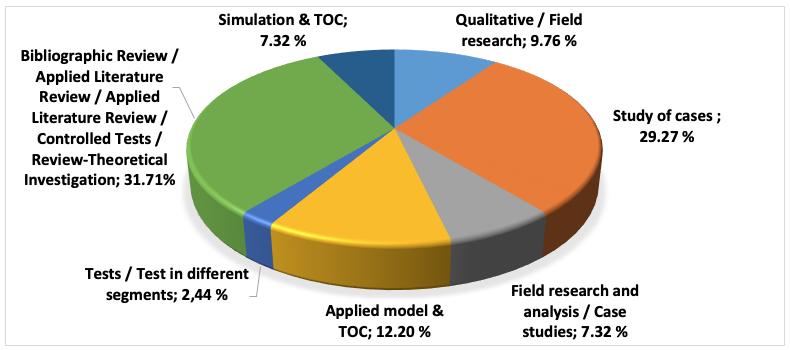

The results show a broad distribution of the methodologies applied in the studies carried out. Seven methodological categories are established, the largest participation is directed to the Bibliographic Review / Applied Literature Review / Controlled Tests / Revision-Theoretical Research, with 36.12%; followed by case studies, with 22.22% of the total classified; Field / Qualitative Research together with field research and analysis / case study both total 19.44%; and, the models / simulators, in a group form, accumulate 22.22% of the total of the sample.

These data allow us to consider that the research has been directed towards the revision of the TOC from its concept and its application in order to increase our understanding of its application, in a scenario where the evolution of the subject has already initiated a process of interaction with several fields of management. However, an intensification in case studies of the business sector is noted as a second research alternative, without discarding the application to model and simulation, which is shown as an important trend in the study of the sample, see Figure 5 , which presents the detailed distribution.

Figure 5

Distribution of publications according to the research methodology

Results considered are discriminated by the categories defined as managements and their corresponding sectors, see table 2.

Table 2

Performance of the Theory of Constraints (TOC) in the business sectors.

Study category |

Specific business sector |

General management. |

Distribution Systems and Logistics. Project Management. Manufacturing / Production and Other areas. |

General Services Management. |

Health. Education. |

Innovation and Systems Management. |

Automotive Maintenance. Furniture Sector. Small companies. General innovation & other areas. |

Due to the importance of the production sector from the management's point of view, we find a high percentage of TOC research as applied theory. Likewise, current research shows the diversification of the TOC application to reduce bottlenecks (Thürer & Stevenson, 2018). In this context, it is known that the participation of business management for the optimization of processes is essential in order to obtain efficient processes (González Gomez, Ortegón, & Rivera, 2003), this is where managers must identify the complexity of their processes by locating bottlenecks (Aguilera, 2000). In this sense, TOC has been applied to production processes (Kahmann, Kloeckner, Zocche, & Cassel, 2014) and, its results are better than other management philosophies that act in a localized way over the cause (local optimization) (Verma, 1997).

In this business context, the publications present an acknowledgment to the practice or application of theory of constraints (TOC) in the management and academic tables (Watson et al., 2007). Additionally, other complementary methods that can be combined with TOC have been created, such as the 5 steps of focus (5FS), continuous improvement techniques, and the management of critical chain projects.

On the other hand, it is evident in the published works, that the TOC, applied to the Project Management, provides a comprehensive solution to address and to deal with the principal cause. The solution includes: a solid planning process, a more effective programming process, a methodology to increase capacity, execution processes that provide excellent control of the project, and decision support, for the good performance of the project.

Additionally, the management of projects and multiple project structures has strengthened the combination of different tools, such as the Critical Chain Project Management (CCPM) (Izmailov et al., 2016a), which is a TOC tool used for the planning and management of projects that allows facing problems such as the difficulty of completing the project in the established time, conflicts between project managers and resource managers, factors that can lead to the project being stopped (Izmailov, 2014). Therefore, the TOC applied to Project Management provides a comprehensive solution to deal with the root cause of the problems.

The TOC has also been implemented to optimize the processes or business distribution systems, and supply chain management (Simić, Kovačević, Svirčević, & Simić, 2017) along with other theories that involve decision making (Sikilero, Rodrigues, Lacerda, Secundino , & Neto, 2014) have been able to adjust to variable processes of inventories, sales planning, and reliability of suppliers (Šukalová & Ceniga, 2015), achieving excellent results in companies of varied activities (food, engineering and wood). Another field of action of the TOC, considers statistical techniques and discrete multicriteria methods with the purpose of improving supply chains for the recycling of plastics (Feitó Cespón, Cespón Castro, Martínez Curbelo, & Covas Varela, 2015), showing usefulness in supply chain systems for the optimization of management strategies for dynamic inventories (Tsou, 2013). Studies that have combined diverse analyzes with thought design and mathematical models to determine constraints on supply chains in commercial areas (Banerjee & Mukhopadhyay, 2016) including sales and cost evaluation (Wen, Ya-Ming, Jinbo, & Kaijun, 2015) have been proposed. Results in both cases, with the implementation of the TOC, capitalized improvements in the reduction of the subsequent work, showed an improved cash flow, a lower operating cost, reduction in the accumulation of orders, a better interaction with the client, including the decrease in the whiplash effect "Bullwhip" (Costas, Ponte, de la Fuente, Pino, & Puche, 2015). Another TOC study has allowed the recognition of restriction points in supply chain replacement systems in plants with different volumes and different products, for the further development of optimal replacement models (Wu, Lee, & Tsai, 2014).

Other interesting results in the manufacturing sector, the work carried out in the area of production planning and control, has shown an optimization of bottle necks when applying TOC, in tests with load flows (Thürer, Stevenson , Silva, & Qu, 2017). Theoretical studies have also been carried out among the TOC, the six sigma and lean manufacturing that conclude in a promising improvement of the manufacturing processes (Pacheco, Jung, & Ten, 2013; Kahmann et al., 2014). Similarly, in plastic manufacturing plants, studies have been presented to optimize costs under approaches that involve combining products and bottle necks (Alsmadi, Almani, & Khan, 2014).

This second category groups the researches done on the application of the TOC, which have concluded in positive results related to the improvement of the processes in entities responsible for providing a service. This has provided useful help for its subsequent application in the educational and hospital sectors, and other related researches. In the same vein, we have the case presented by Fekri et al., (2012), which set out to determine and compare the effectiveness of business education from a Multi-Axial Model and, the Theory of constraints. Conclusions determined that they are efficient to measure the business skills of students of humanities and this allowed to establish better strategies of commitments in the study of business skills. On the other hand, the optimization of the restrictions on academic production in the university sector can be improved by applying the TOC methodology, which allows systematically recognizing the restrictions for their subsequent optimization (Metlich, 2006).

In the area of hospital services, physical storage restrictions and logistic services policies of medical records were studied and with the application of the TOC, results were obtained that showed important increases in service and productivity, in costs and satisfied patients. (Aguilar-Escobar et al., 2016). Another research showed that TOC can optimize the billing system of no-profit hospitals, due to inconsistencies in data entry of invoices issued by administrative and medical operators (López, Urrea, & Navarro, 2006). At the same time, an improvement of the commercial system is achieved, measured in terms of products, feasible services and maintaining the flow of customers (Gupta, Bridgman, & Kaur Sahi, 2015). Other studies carried out in primary health care centers, which have involved computer simulation support and the application of TOC, have concluded that in order to improve patient care capacity, restrictions must be exploited (Sartor, Dos Santos A, & Pizarro, 2014).

This third category considers studies related to the use of support systems, using software for the simulation of processes. It is highlighted that organizations are focusing their management efforts on the adoption of new technologies and new administrative models with the support of optimization methodologies (Bagno, Salerno, & Dias, 2017). The TOC is participating in the evaluation of multiple business processes with the support of systems that complement the determination of restrictions, which reduce the free flow of operations in any productive and financial area (Altug & Firat, 2018). The results allow us to realize the interaction between the TOC methodology and computer systems for the simulation and improvement of business efficiency (Alves, Azevedo, & Pizarro, 2014).

Other implications of the TOC in the automotive sector, have allowed to optimize the production schedules, and together with other optimization methods (Mantovani, Presti, Cavazzoni, & Baldini, 2017) integrate opportunities for improvement, by performing simulations of the processes (Golmohammadi, 2015). Additionally, the studies carried out in companies in the mechanical and automotive sector, combined lean manufacturing and TOC methodology, optimized the satisfaction of internal and external customers, and presented a global improvement to the company (Marulanda, Hincapié, & Echeverry, 2016). Likewise, other investigations have managed to integrate the modeling of processes using value stream mapping and TOC in the processes of a Brazilian automotive industry, proposing improvements with lean (Pereira Librelato, Pacheco Lacerda, Henrique Rodrigues, & Rafael Veit, 2014). In this scenario, TOC has managed to improve the efficiency of production costs of high quality vehicles, allowing business management to be in harmony with budgets (Huang, Chen, Chiu, & Chen, 2014).

In another area of services, the industrial maintenance sector has been able to improve its production systems with the implementation of TOC, TPM (Total productive maintenance) and production simulators (Sanchez, 2005), allowing management decisions to be made during the interruption of industrial processes due to industrial breakdowns and equipment failures. Another specific business sector, the shoe manufacturing industry, has improved its operational utility as a result of the application of the TOC, and has allowed the generation of new optimization models (Ortiz-T, & Caicedo-R, 2014), for the detection of critical operations. Together with dynamic, discrete and stochastic models, the TOC has allowed the recognition of critical restriction points (Alves, et al., 2014) and improved customer flows in restaurants. Additionally, TOC has expanded its application as a management and cost accounting tool in furniture manufacturing organizations to improve production times and timely deliveries (Okutmuş et al., 2015). All these results are connected with the line of increasing the efficiency and effectiveness of the services (Ardila, J.G., Ardila, M.I., Rodríguez, & Hincapié, 2016), applying the TOC in each of the areas presented here.

The literature review allowed us to know about the tendency of TOC research in companies dedicated to the different business sectors, which included project management, production, logistics and distribution, educational systems, hospitals, which by their nature involve administrative and operational sequential processes. In this sense, the application of the theory of constraints showed a great level of acceptance at managerial levels, due to its versatile philosophy that allows identifying the bottleneck that produces a decrease in the different organizational systems of production, from the simplest to the most complex. Currently TOC is being used together with other mathematical models of optimization and simulation to detect critical points or restrictions. It should also be noted that the theory of constraints, although its conception was to be applied in private companies, can now be used in the public sector.

Another interesting point to be considered from the review, is that it is a theory which publications have progressively increased: In the period 2014-2018 publications increased in 75.61% related to what was published in the previous period 1997-2013 with 24.39%. This allows us to conclude that we are facing a theme that promises a progressive increase in its publications with different applications in companies, at the same time management considers it a satisfactory methodology to improve general processes. However, it is expected to obtain more studies related to the implementation of TOC and different investigative approaches to broaden this topic and continue contributing with science.

Alsmadi, M., Almani, A., & Khan, Z. (2014). Implementing an integrated ABC and TOC approach to enhance decision making in a Lean context. International Journal of Quality & Reliability Management, 31(8), 906–920. https://doi.org/10.1108/IJQRM-04-2013-0063

Altug, S., & Firat, M. C. (2018). Borrowing constraints and saving in Turkey. Central Bank Review, 18(1), 1–11. https://doi.org/10.1016/j.cbrev.2018.01.002

Aguilar-Escobar, V. G., Garrido-Vega, P., & González-Zamora, M. del M. (2016). Applying the theory of constraints to the logistics service of medical records of a hospital. European Research on Management and Business Economics, 22(3), 139–146. https://doi.org/10.1016/j.iedee.2015.07.001

Aguilera, C. (2000). Un enfoque gerencial de la teoría de las restricciones. Estudios Gerenciales, 16(77), 53-69. Retrieved from http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S0123-59232000000400004&lng=en&tlng=es.

Ardila, J., Ardila, M., Rodríguez, D., & Hincapié, D. (2016). La gerencia del mantenimiento: Una revisión. Dimensión Empresarial, 14(2), 127- 142. https://dx.doi.org/10.15665/rde.v14i2.480

Alves, R., Azevedo, J., & Pizarro, C. (2014). Aplicação dos princípios da teoria das restrições e de técnicas de simulação na gestão da dinâmica operacional de um pequeno restaurante: um estudo de caso. Espacios, 35 (7), p. 21. Retrieved from

http://www.revistaespacios.com/a14v35n07/14350721.html

Avraham & Goldratt Institute. (2009). The Theory of Constraints and Thinking Processes. Retrieved from http://www.everydaykanban.com/wp-content/uploads/2013/05/the_theory_of_constraints_and_its_thinking_processes.pdf

Bagno, Raoni Barros., Salerno, Mario Sergio., & Dias, Ana Valeria Carneiro. (2017).

Innovation as a new organizational function: evidence and characterization from large industrial companies in Brazil. Production, 27, e20162073. https://dx.doi.org/10.1590/0103-6513.207316

Banerjee, A., & Mukhopadhyay, S. K. (2016). A contemporary TOC innovative thinking process in the backdrop of leagile supply chain. Journal of Enterprise Information Management, 29(3), 400–431. https://doi.org/10.1108/JEIM-08-2014-0086

Bardin, L. (2002). Análisis de contenido. 3era edición. Madrid: Ediciones Akal. 181 pag. Retrieved from: www.//books.google.com.ec/books?id=IvhoTqll_EQC&printsec=frontcover&source=gbs_ge_summary_r&cad=0#v=onepage&q&f=false

Costas, J., Ponte, B., de la Fuente, D., Pino, R., & Puche, J. (2015). Applying Goldratt’s Theory of Constraints to reduce the Bullwhip Effect through agent-based modeling. Expert Systems with Applications, 42(4), 2049–2060. https://doi.org/10.1016/j.eswa.2014.10.022

Feitó Cespón, M., Cespón Castro, R., Martínez Curbelo, G., & Covas Varela, D. (2015). Diagnóstico ecológico y económico de la cadena de suministros para el reciclaje de plásticos en el contexto empresarial cubano. Estudios Gerenciales, 31(136), 347–358. https://doi.org/10.1016/j.estger.2015.03.005

Fekri, K., Shafiabady, A., Nooranipour, R., & Ahghar, G. (2012). Determine and Compare Effectiveness of Entrepreneurship Education based on Multi- Axial Model and Theory of Constraints and Compromises on Learning Entrepreneurship Skills. Procedia - Social and Behavioral Sciences, 69, 566–570. https://doi.org/10.1016/j.sbspro.2012.11.447

Ferreiro, L. (1995). Análisis Bibliométrico Bivariante. Madrid: Editorial Eypasa.

Golmohammadi, D. (2015). A study of scheduling under the theory of constraints. International Journal of Production Economics, 165, 38–50. https://doi.org/10.1016/j.ijpe.2015.03.015

Goldratt, E. (2008). Necesario pero no suficiente, una novela de negocios sobre la teoría de Restricciones. Buenos Aires, Argentina: Granica.

Goldratt, Eliyahu M. (1996). La Meta. Estados Unidos: North River press.

González de Dios, J., Moya, M., & Mateos Hernández, M. (1997). Indicadores Bibliométricos: Características y limitaciones en el análisis de la actividad científica. Anales Españoles de Pediatría, 47(3), 235-244.

González Gomez, J., Ortegon, K., & Riviera, C. (2003). Desarrollo de una metodología de implementación de los conceptos de TOC (Teoría de las restricciones), para empresas Colombianas. Estudios Gerenciales, 19(87), 27-49. Retrieved May 10, 2018, from http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S0123-59232003000200002&lng=en&tlng=es.

Gupta, M. C., Bridgman, S., & Kaur Sahi, G. (2015). Application of TOC-based framework to improve market orientation in a non-profit organization. Journal of Strategic Marketing, 23(7), 579–599. https://doi.org/10.1080/0965254X.2014.1001865

Huang, S. Y., Chen, H. J., Chiu, A. A., & Chen, C. P. (2014). The application of the theory of constraints and activity-based costing to business excellence: The case of automotive electronics manufacture firms. Total Quality Management and Business Excellence 25(5–6), 532–545. https://doi.org/10.1080/14783363.2013.820023

Izmailov, A. (2014). If Your Company is Considering the Theory of Constraints. Procedia - Social and Behavioral Sciences, 150, 925–929. https://doi.org/10.1016/j.sbspro.2014.09.103

Izmailov, A., Korneva, D., & Kozhemiakin, A. (2016). Effective Project Management with Theory of Constraints. Procedia - Social and Behavioral Sciences, 229, 96–103. https://doi.org/10.1016/j.sbspro.2016.07.118

Kahmann, A., Kloeckner, A., Zocche, L., & Cassel, R. (2014). Teoria das Restrições e Gestão de Projetos – Corrente Crítica: Uma Revisão Sistemática de Literatura. Espacios, Vol 35(13), p3. Retrieved from http://www.revistaespacios.com/a14v35n13/14351303.html

López López, I., Urrea Arbeláez, J., & Navarro Castaño, D. (2006). Aplicación de la Teoría de Restricciones (TOC) a la gestión de facturación de las Empresas Sociales del Estado, ESE. Una contribución al Sistema de Seguridad Social en Colombia. Innovar, 16 (27), 91-100. Retrieved from https://revistas.unal.edu.co/index.php/innovar/article/view/19178

López, L. P. (1996). Introducción a la Bibliometría. Valencia: Promolibro.

López Piñero, J. M., & Terrada Ferrandis, M. L. (1992). Los indicadores bibliométrico y la evaluación de la actividad médico-científica: los indicadores de producción, circulación y dispersión, consumo de la información y repercusión. Medicina clínica, 98(4), 142- 148.

Mantovani, S., Presti, I. Lo, Cavazzoni, L., & Baldini, A. (2017). Influence of Manufacturing Constraints on the Topology Optimization of an Automotive Dashboard. Procedia Manufacturing, 11, 1700–1708. https://doi.org/10.1016/j.promfg.2017.07.296

Marulanda. Grisales, N., Hincapié. Pizza, E., & Echeverry. Correa, F. (2016). Caracterización de la implementación de lean manufacturing vs teoría de restricciones: Estudio de caso colombiano. Espacios, Vol 37 (25), p 24. Retrieved from http://www.revistaespacios.com/a16v37n25/16372524.html

Melendez, J., Malvacias, A., & Almeida, A. Importance of the participation of the employee in the execution of projects: Management perspectives. (2018). Revista Espacios, Vol 39(14), p 21. Retrieved from http://www.revistaespacios.com/a18v39n14/18391421.html

Metlich, Ana Isabel. (2006). Contribuciones de la teoría de la organización a la productividad científica. Innovar, 16(27), 132-137. Retrieved May 11, 2018, from http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S0121-50512006000100010&lng=en&tlng=es.

Okutmuş, E., Kahveci, A., & Kartašova, J. (2015). Using theory of constraints for reaching optimal product mix: An application in the furniture sector. Intellectual Economics, 9(2), 138–149. https://doi.org/10.1016/j.intele.2016.02.005

Ortiz-T, Viviana Karolina, & Caicedo-R, Álvaro Junior. (2014). Mezcla óptima de producción desde el enfoque gerencial de la contabilidad del throughput: el caso de una pequeña empresa de calzado. Cuadernos de Contabilidad, 15(37), 109-133. Retrieved April 30, 2018, from http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S0123-14722014000100005&lng=en&tlng=.

Pacheco, D., Jung, C., & Ten Caten, C. (2013). Teoria das Restrições e Seis Sigma: limites e possibilidades de integração para a melhoria contínua.Espacios, Vol 34 (11), p 8. Retrieved from http://www.revistaespacios.com/a13v34n11/13341108.html

Paredes, E., & Pérez Urbina, N., & Ramos de Francisco, C. (2005). Gestión de información para medir la producción y productividad científica de la Facultad de Ciencias de la Universidad Central de Venezuela. Enl@ce: Revista Venezolana de Información, Tecnología y Conocimiento, 2 (1), 47-63.

Pereira Librelato, T., Pacheco Lacerda, D., Henrique Rodrigues, L., & Rafael Veit, D. (2014). A process improvement approach based on the Value Stream Mapping and the Theory of Constraints Thinking Process. Business Process Management Journal, 20(6), 922–949. https://doi.org/10.1108/BPMJ-07-2013-0098

Price, D. J. (1963). Little science, big science. . New York: Columbia University Press.

Rangel, J. R. M., Salazar, J. L. D., Salazar, G. V., Malvacias, A. M., & Vacacela, R. G. (2017). Gestión Del Riesgo Psicosocial. Visión Gerencia Compartida Del Escenario Emergente en la Realidad Organizacional. Empresarial, 11(42), 7-15. Retrieved from https://scholar.google.com/scholar?oi=bibs&hl=es&cluster=1957207322981532568

Ruiz-Torres, A. J., Ayala-Cruz, J., Alomoto, N., & Acero-Chavez, J. L. (2015). Revisión de la literatura sobre gestión de la calidad: caso de las revistas publicadas en Hispanoamérica y España. Estudios Gerenciales, 31(136), 319–334. https://doi.org/10.1016/j.estger.2015.01.004

Salazar, J., Villavicencio, C., Corral, P., & Melendez, J. (2017). Principio Contaminador y pagador. Observatorio de la Economía, Grupo Eumed.net (Universidad de Málaga), issue 233, July. Retrieved from http://www.eumed.net/cursecon/ecolat/ec/2017/contaminador-pagador-ecuador.html

Sanchez, Carlos Alberto. (2005). Impacto de las averías e interrupciones en los procesos. Un análisis de la variabilidad en los procesos de producción. DYNA, 72(145), 67-75. Retrieved April 30, 2018, From http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S0012-73532005000100007&lng=en&tlng=es.

Sartor, F., Dos Santos A, J., & Pizarro, C. (2014). Teoria das restrições e simulação aplicadas no gerenciamento de demanda de uma unidade de pronto atendimento. Espacios, Vol 35 (4), p 18. Retrieved from http://www.revistaespacios.com/a14v35n04/14350403.html

Sikilero, C., Rodrigues, L., Lacerda, D., Secundino, L., & Corcini, S. (2014). Gestão da Cadeia de Suprimentos: uma reflexão a partir da Teoria das Restrições.Espacios, Vol 35(4), p 3. Retrieved from http://www.revistaespacios.com/a14v35n04/14350403.html

Simić, D., Kovačević, I., Svirčević, V., & Simić, S. (2017). 50 years of fuzzy set theory and models for supplier assessment and selection: A literature review. Journal of Applied Logic, 24, 85–96. https://doi.org/10.1016/j.jal.2016.11.016

Şimşit, Z. T., Günay, N. S., & Vayvay, Ö. (2014). Theory of Constraints: A Literature Review. Procedia - Social and Behavioral Sciences, 150, 930–936. https://doi.org/10.1016/j.sbspro.2014.09.104

Spinak, E. (1996). Diccionario enciclopédico de Bibliometría, cienciometría e informetría. Caracas. Retrieved http://unesdoc.unesco.org/images/0024/002433/243329S.pdf

Šukalová, V., & Ceniga, P. (2015). Application of the Theory of Constraints Instrument in the Enterprise Distribution System. Procedia Economics and Finance, 23, 134–139. https://doi.org/10.1016/S2212-5671(15)00445-1

Thürer, M., Stevenson, M., Silva, C., & Qu, T. (2017). Drum-buffer-rope and workload control in High-variety flow and job shops with bottlenecks: An assessment by simulation. International Journal of Production Economics, 188, 116–127. https://doi.org/10.1016/j.ijpe.2017.03.025

Thürer, M., & Stevenson, M. (2018). Bottleneck-oriented order release with shifting bottlenecks: An assessment by simulation. International Journal of Production Economics, 197, 275–282. https://doi.org/10.1016/j.ijpe.2018.01.010

Tsou, C. M. (2013). On the strategy of supply chain collaboration based on dynamic inventory target level management: A theory of constraint perspective. Applied Mathematical Modelling, 37(7), 5204–5214. https://doi.org/10.1016/j.apm.2012.10.031

Verma, R. (1997). Management science, theory of constraints/optimized production technology and local optimization. Omega, 25(2), 189–200. https://doi.org/10.1016/S0305-0483(96)00060-6

Watson, K. J., Blackstone, J. H., & Gardiner, S. C. (2007). The evolution of a management philosophy: The theory of constraints. Journal of Operations Management, 25(2), 387–402. https://doi.org/10.1016/j.jom.2006.04.004

Wen, Z., Ya-Ming, Z., Jinbo, C., & Kaijun, L. (2015). Research on a scheduling mechanism in a complex system based on TOC. Chaos, Solitons and Fractals, 89, 335–347. https://doi.org/10.1016/j.chaos.2015.12.017

Wu, H. H., Lee, A. H. I., & Tsai, T. P. (2014). A two-level replenishment frequency model for TOC supply chain replenishment systems under capacity constraint. Computers and Industrial Engineering, 72, 152–159. https://doi.org/10.1016/j.cie.2014.03.006

1. Doctor (Ph.D) in management. MSc in finance and business management. Universidad Catolica de Santiago de Guayaquil, Ecuador. Professor and researcher. e mail: jesus.melendez@cu.ucsg.edu.ec

2. Chemical engineer. Universidad de Los Andes, Mérida, Venezuela. Facultad de Ingeniería. Departamento de Operaciones Unitarias y Proyectos. Professor and researcher. email : yamilz@ula.ve

3. MD. Instituto Ecuatoriano de seguridad social (IESS). researcher. e-mail: annymalvacias@yahoo.es

4. MSc in teaching English foreign language MTEFL. Universidad Catolica de Santiago de Guayaquil, Ecuador. Professor and researcher e-mail: annabelle_almeida@yahoo.com