1. Introduction

Management of technology and innovation have become the constituent keys to acquire competitive advantages (Burgelman, 2009), (Tid, 2009), to guarantee the growth (Dismukes, 2005), to assure the permanence on time and to generate advanced technology (Merrifield, 1999); one of the forms to materialize technological management, is through technological functions (Morin and Seurat, 1998), in which prospective and technological Surveillance can be found.

In this work, through an exercise of technological surveillance and another one of prospective with the Delphi method (Balaraman S, and Venkatakrishnan K, 1980), the following things were identified: The main characteristics of the research tendencies in the development and implementation of advanced steel used in the manufacture of parts for vehicles, research centers in this field, the scientific companies that are working on the subject, the related patents and publications around this thematic that are being carried out, among others sources of information.

A study of this type is important because in any country, the automotive industry displays a great dynamism of technological development and innovation in different orders: Materials for the manufacture of the diverse parts that make up a vehicle, electrical and electronic components, among others factors.

The main used sources of information for the cycle of TS were the data base of scientific articles Sciencedirect and patents, (Office of Marks and Patents of the United States and the European Patents Office), and in its processing and analysis, the computer science tool VantagePoint and Delphion were used.

The exercise of prospective with the Delphi method was conducted at three rounds and it counted with the participation of professionals from groups of investigation in materials and companies of the automotive sector with experience and knowledge in the subjects being studied.

2. Sector problem

The reduced technological capacity constitutes a disadvantage for the Colombian suppliers of automobile parts, where the high cost of development of innovations becomes a disadvantage for companies of low financial standing. This gives rise to a selective process and concentration of the suppliers, to which, these try modernizing their productive processes (DNP, 2006).

The processes of innovation based on TS and CI (Competitive Intelligence) facilitate the answer in a global scale, on the part of the companies, the universities and institutions of the government promoting productive development, and generally to almost any type of organization (Vásquez J. and Ortegón M.)

In the case of the materials, it requires tools of technological management that support the search of information for the formulation and management of projects of basic and applied investigation in new or already established areas of knowledge and also the technological transference in the production and acquisition of materials for the Colombian automotive industry, in order to be on a par in their development with the international tendencies.

It should be noted that the sector of manufacture of parts for vehicles in Colombia was selected in the second semester of 2008 as one of world-wide class, by a set of organizations, in which some dependencies of the government are part of, which implied the accomplishment from that year of a series of activities to harness this line of the national economy, being one of these, the work with advanced materials in replacement of the conventional ones (MCIT, 2009).

3. Methodology

3.1 The materials in the automotive sector

Regarding the materials for the industry, a series of factors have been identified that guide the main applications of these in the construction of automobiles (Azkárate G., 2001).

• Structural materials of high absorptivity of energy

• Design and development of intelligent materials and structures

• Development of methods of prediction and testing of primary structures in compound materials.

• Advanced technologies of manufacture in compound materials

• Development of economically recyclable components.

• Intelligent materials (actives) for the attenuation of the internal noise

• New absorbent materials which are light and of low cost (actives)

• New materials more efficient and tolerant to damage

• Development of materials considering inflammability, toxicity and smoke-screening and good behavior to impact.

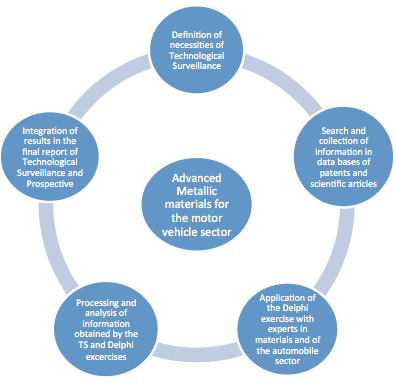

Figure 1 shows a scheme of the methodology for the development of exercises of Technological Surveillance and Prospective with the Delphi method. In the end of the figure, the results of the data obtained with the execution of both exercises are integrated.

Figure 1. Scheme of the methodological development of the exercises of TS and Prospective.

It was meant to give answer to the following necessity: Tendencies in used metallic materials in the construction of vehicles.

3.2 Technological Surveillance

Technological Surveillance (TS) and Competitive Intelligence (CI) represent a systematic process in which it captures, analyzes and spreads information of diverse nature - economical, technological, political, social, cultural, legislative - , by means of legal methods, with the intention of identifying and anticipating opportunities or risks, to improve the formulation and execution of the strategy of the organizations (Escorsa, P. and Maspons, R., 2001).

At the moment, it is considered that the acquirement of information and knowledge in a systematic form, are elements of great importance for any type of organization, which are contributed to assure the organization's profitability and survival. The great present competitiveness, forces companies to constantly remain informed of everything which surrounds them, structuring in this way the function of TS at the company, where suitable information should be provided to the makers of decisions, the top management, at the opportune moment (Castell, E. and Pasola, V., 1997).

To deepen theory, to understand and apply means like Technological Surveillance, are important aspects that any organization must have present, or even at a personal level, to gather changes that follow one another in the surroundings and thus be able to define strategies of answer and anticipation to these, in order to improve more and more against certain standards (Cross, E., Escorsa, P. and Maspons R., 2003).

The investigation was conducted with a review of scientific articles within the data base Sciencedirect and with the consultation of patents with the analyses and search tool Delphion, with which a registry was made in the main data bases of patents around the world, the Office of Patents and Marks of the United States and the European Patents Office, among others.

The window of time used for these searches took in account the period between the years 2000 and June of 2010, being considered reasonable for establishing tendencies.

3.3 Prospective

The prospective can be defined as a systematic and participating process for compiling knowledge about the future and for constructing visions in the medium and long term, with the aim of informing the decisions which are to take in the present and to mobilize joint operations (CE, 2002).

The future studies are part of the following basic principles:

• As a starting point, in order to know the future it is required to know the past and the present, where knowledge can generate a wide range of possible or desirable futures.

• The future can be constructed, in which one can have a great impact over, in agreement with the aspirations of a determined collective.

• The future can also be studied by relating the options, values and principles of a social group and that are different between generations and cultures.

3.4 Delphi method

It is regularly defined as a method to structure the process of group communication, making it effective to allow a group of individuals, as a whole, to deal with complex problems (Builes, C. and Manrique J., 2000).

In the execution of this exercise, a group of topics were obtained from the first round which was identified as high-priority by the expert panelists. This selection of topics was performed with base in the modal qualification of four or five (5, high priority; 0, no priority) and where, in addition, a percentage of consensus was reached superior to 40%.

A second set of topics was catalogued as group in Discussion, since it displayed a statistical fashion of 4 or 5, although its percentage of consensus was inferior to 40%. The third and last group corresponded to the no priority topics with qualifications fewer than 4 with any percentage of consensuses.

According to the previous results, a questionnaire for the second round was elaborated, where the group of high-priority topics appeared and in discussion for the studied subject (advanced steel), in which expert panelists identified if some of the topics in discussion should be now considered as high-priority, allowing them to enter in exchange for some qualified as these last ones in the first round.

In this last stage, those topics subjects that reached a consensus superior to 40% were selected as high-priority (in the measurement by consensus and the measurement by points). It was proceeded to elaborate a closing report with the content of a list of topics and high-priority lines of investigation in the field of the metallic materials to produce automobile parts for the Colombian automotive industry and the markets of export with a horizon to the year 2020.

4. Results

The management of the knowledge stored in the data bases of patents and scientific articles help transform the data into information, the information in knowledge and this in understanding, that is to say, elements to innovate (Commanded, E., Fernandez, F. and Doiro, M., 2003).

4.1 Exercise of Technological Surveillance

With this technique, the technologies available are studied as much as the emergent ones that can be used in new products or processes, and in addition identifies changes and future tendencies, making it available for a company to grant certain advantages over its competitors, and also to guide their strategies of investigation (Ortíz, I., Escorsa, P. and others, 2006).

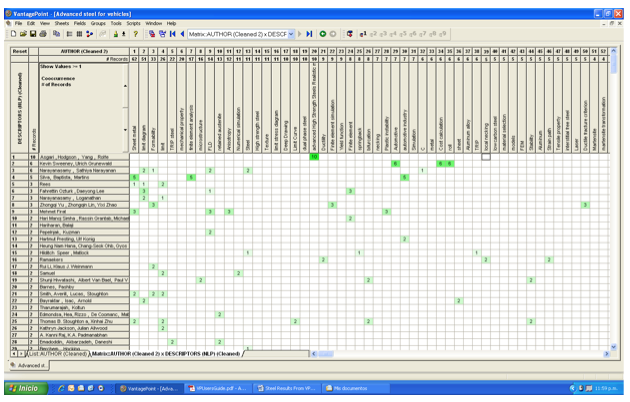

Figure 2 shows the Co-occurrence between the descriptors (key words) and authors. It is observed, for example, the association between the authors Asgari, Hodgson, Yang and Rolfe with the thematic of simulation of processes of manufacture and parts in advanced steel.

Figure 2. Matrix of co-occurrence between authors and key words

In figure 3, it is observed that in the recent years from 2006 to 2009, the topics of "Trip" steel, diagrams of stress limit, formability, analysis by finite elements and simulation models, continue having a wide field of investigation.

Figure 3. Matrix of Co-occurrence between key words and year of publication

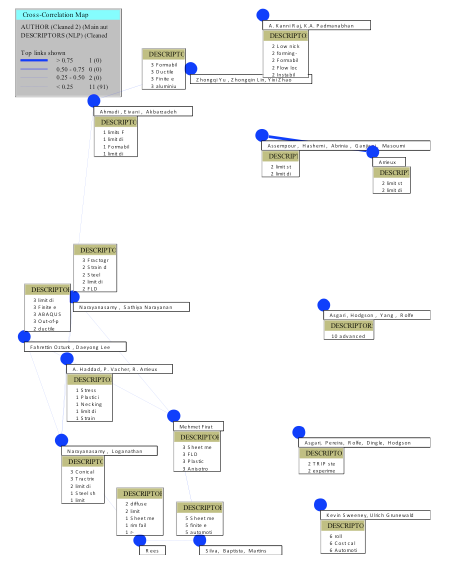

Figure 4 shows the authors who are working in similar topics. For example: Silva, Baptista and Martins, authors which publish on analysis with finite elements. Mehmet Firat also works the diagrams of stress limit, while authors Asgari, Pereira, Rolfle, Dingle and Hodgson work on steel advanced like the "Trip." The sharp lines indicate some common thematic in their investigations.

It is also observed that there are some common elements, on which different authors are investigating, this being given by the connections with the sharp lines. The strongest relation, expressed by the greater thickness of the line, occurs between the group of authors Assempour, Hashemi, Abrinia, Ganjiapi and Masoumi, who appear in this set of scientific articles, working on similar topics such as stress limit and limit diagram.

Figure 4. Map of Cross-correlation between authors and key words (Descriptors).

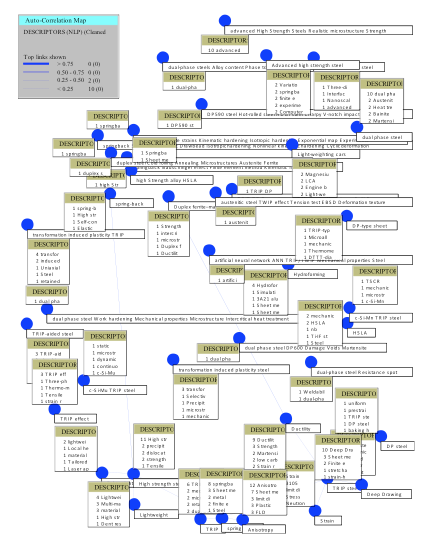

In figure 5, it is possible to appreciate a high correlation between different terms associated to advanced steels, for example strain, steel trip, steel dual phase, Diagrams of Stress Limit (FLD), simulation, finite elements, springback, among others.

Figure 5. Map of Auto-Correlation between key words.

4.2 Results from patent search

Equation of the implemented search for advanced steel materials of ultra high resistance,

(((ultra high strength steel) AND (automotive) AND (vehicle)) AND (PD>=2000-01-01)) AND (PD<=2000-08-20).

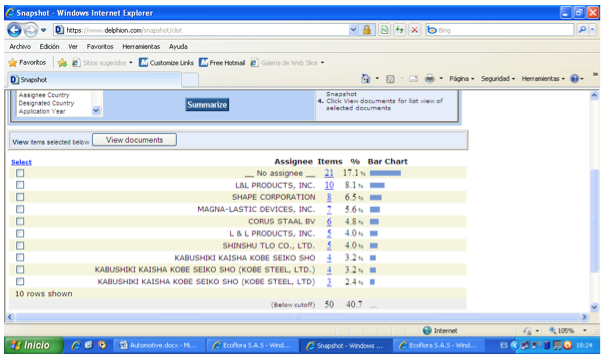

In regards to the organizations or companies that appear as possessors of the patents of products fabricated with Trip advanced steel, in figure 6, L&L Products are mainly found with 10 published patents. L&L Products is an important international company that designs and produces parts for the automobile and aerospace industries. One of its main field works is the design and experimentation with structural systems for automobiles produced in advanced materials for vehicles, like for example, the bodywork, where they also experiment with Aluminum and Magnesium (L&L Products, 2010).

Another important organization is Shape Corporation, which is shown as possessor of 8 patents in this topic of manufacture of automobile parts. It also appears as the world-wide leader supplier of bumper systems when providing an integral service in design, engineering, test and manufacture of these pieces, with innovating proposals in materials, reduction of weight, shapes, and competitive costs (Shape Corp., 2010).

Figure 6. Assignee of patents of the Trip steel

In figure 7, it is appreciated the leading countries in the investigation and development of automobile parts made in the Trip advanced steel, where the United States of America stands out with 50 assigned patents, Japan with 16, France with 8 and Holland also with 8. The previous statement is also consequent with the idea that these countries own a strong automotive industry with an ample tradition.

Figure 7. Countries of origin of the patents of Trip steel

4.3 Results of the prospective exercise with Delphi method in regards to the family of advanced steel.

4.3.1 Results of the percentage by points in the three rounds

Figure 8 shows the values of the percentages by points obtained in the three rounds for each topic selected as high-priority by the panel of experts.

It is observed that the topics that exceed a score of 60 in regards to advanced steel are:

• Costs of manufacture of automobile parts (1.2)

• Formation and practice in the use of these materials (1.3)

• Materials for the manufacture of matrices (1.4)

• Simulation by finite elements (2.2)

• Study of the curves of limit of formability of the thin plates/layers (2.3)

• Weight reduction of diverse parts (2.5)

• Processes of printing (3.4)

Figure 8. Percentage by points for the different topics selected as high-priority.

4.3.2 Results of the percentage of consensus in the three rounds

Figure 9 shows the values of the percentage by consensus obtained in the three rounds for each topic selected as high-priority by the panel of experts.

It is observed that no topics corresponding to advanced steel material surpassed a percentage of consensus of 60% and were only over 40% (Round 3), the topics:

• Costs of manufacture of automobile parts (1.2)

• Materials for the manufacture of matrices (1.4)

• Processes of metal forming (3.4)

Figure 9. Percentage of consensus for the different topics selected as high-priority.

4.3.3 Final selection of topics in the third round

From the statistic analysis as far as the comparison between the results of the percentage of consensus reached for each topic in the third round (R3), in regards to the percentage by points also found in this round with 28 participants, the topics are obtained by consensus and points for the material corresponding to advanced steel.

For the final selection of high-priority topics, the criteria was defined in the first round about establishing these as ones that reached a percentage of equal consensus or superior to 40% and corresponded to:

• Costs of manufacture of automobile parts (1.2)

• Formation and practice in the use of these materials (1.3)

• Materials for the manufacture of matrices (1.4)

• Simulation by finite elements (2.2)

• Study of the curves of limit of formability of the thin plates (2.3)

• Weight reduction of diverse parts (2.5)

• Processes of metal forming (3.4)

• Forge

5. Conclusions

An important area of investigation is the use of software of applicable simulation in different aspects of materials, like for example, the one of optimization of the production processes.

Important fields of investigation continue to be the improvement of the mechanical properties of alloys corresponding to advanced steel and new applications for these in the manufacture of different parts for automobiles.

The use of advanced materials entails to adapt the processes of design and tools of transformation of the conventional materials.

The metallic materials used to make automobile parts continue to be an effective field for the formulation and execution of innovation projects and technological development.

The use of the tools of technological and prospective surveillance with the Delphi method, turns out to be very useful for the identification of lines of investigation in a determined thematic, the reason being that they allow combining the results of the search of information in extensive data bases of scientific articles and patents, with the particular needs and expectations of the actors of a determined technological problem.

References

- Azkárate, G. "Tendencias Tecnológicas del Transporte, Horizonte de 2015". INASMET, Centro Tecnológico de Materiales. Economía industrial, no. 342, 2001.

- Balaraman, S y Venkatakrishnan, K. S. 1980. Identifying Engineering Education Goals and Priorities for the Future: an experiment with the Delphi technique. Higher Education 9 53-67.

- Builes, C. y Manrique J. Las prioridades investigativas en ingeniería mecánica: Un estudio prospectivo en Antioquia. Medellín: UPB, 2000.

- Burgelman, A. 2009 Strategic management, McGraw Hill.

- Castell, E. y Pasola, V. Manual de gestión e innovación tecnológica en la empresa. Santiago de Chile: CINDA-AECI, 1997.

- Comisión Europea. Guía práctica de prospectiva regional en España. Luxenburgo, 2002.

- Cruz, E., Escorsa, P. y Maspons, R. La vigilancia tecnológica en el sector de los nuevos materiales. Madrid: IALE Tecnología, 2003.

- Departamento Nacional de Planeación (DNP). Cadenas productivas - Automotor. Estructuras, comercio internacional y protección. Bogotá: DIAN, 2004.

- Dismukes, J.P.2005. Information Accelerated Radical Innovation From Principles to an Operational Methodology, The Industrial Geographer, Vol. 3 no, 1. p. 19-42.

- Escorsa, P. y Maspons, R. De la vigilancia tecnológica a la inteligencia competitiva. Financial Times. Madrid: Prentice Hall, 2001.

- Mandado, E.; Fernández, F. y Doiro, M. La innovación tecnológica en las organizaciones. Madrid: IEA Universidad de Vigo, 2003.

- Merrifield, D. B. 1999. Innovation Management in the 7Th Great Epoch, Research Technology Management, Vol 42, p 10-14.

- Ministerio de Comercio, Industria y Turismo. (2009) Conociendo los sectores de clase mundial Colombia.[En línea]. Disponible: http://www.mincomercio.gov.co/eContent/newsdetail.asp?id=6569&idcompany.

- Morin, J. y Seurat, R. 1998. Gestión de los Recursos Tecnológicos, Fundación Cotec para la innovación tecnológica. Madrid.

- Ortíz, I., Escorsa, P. y otros. El acontecer mundial en biopolímeros a través de los resultados de la VT; en: la Prospectiva Tecnológica e Industrial. Bogotá: Colciencias-CAF, 2006.

- L&L Products. (2010) Information. [En línea] Disponible: http://www.llproducts.com/index.hTSl.

- Shape Corp. (2010) [En línea] Disponible: http://www.shapecorp.com.

- Tidd, J. 2009. Managing Innovation, Integrating Technological, Market and Organizational Change. Vol. 4 no. Cap 1, p.17.

- Vásquez, J. Medina y Ortegón, M. Edgar. Manual de prospectiva y decisión estratégica: Bases teóricas e instrumentos para América Latina y el Caribe. Chile: ILPES, 2006.